Every year in spring, the Hermle open house is a regular appointment for all of the company’s customers and employees. In the same way, following the tradition, the German company presents its latest innovations during this event. This year, due to the coronavirus emergency and the measures imposed by governments to fight the spread of the pandemic, the eagerly awaited event at Hermle has been cancelled. However, the company was not discouraged and launched its latest innovation HS flexy heavy.

The company’s commitment in terms of improvement in the field of automation is the same as its commitment and efforts in the digital field. Hermle therefore demonstrates that the two themes are at the heart of the company’s development dynamics. If, in the digital field, Hermle has just launched the “Navigated” control interface and the configurable “Home” screen, with Hs flexy heavy, Hermle intends to further develop the previous solution for pallet handling HS flex that has already been on the market for some time. Hs flex heavy is a solution that increases the load that can be carried when handling workpieces via multi-axis machining centres up to 1200 kg.

A single word: Automation

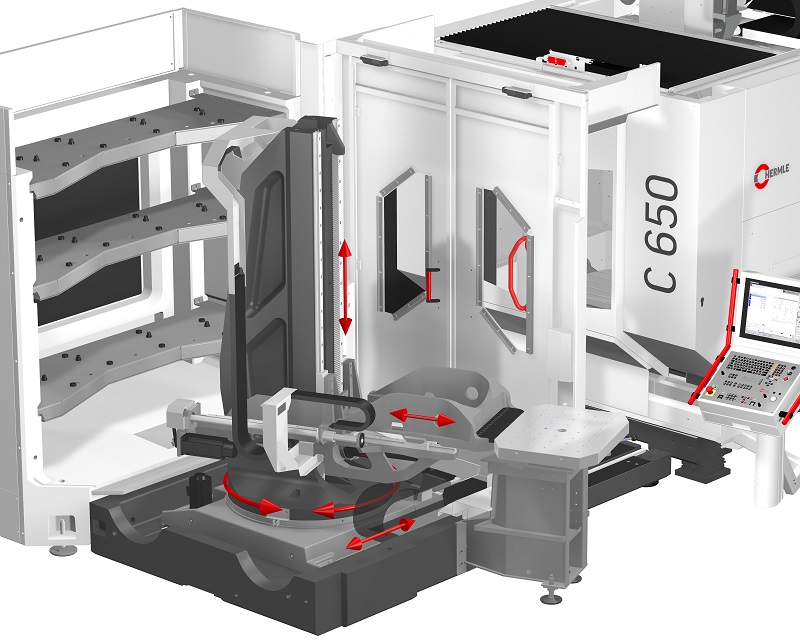

The new solution presented by Hermle continues the company’s 20-year tradition of focusing on the development of increasingly automated machining processes on board its machining centers. Hs flex heavy presents itself as a very versatile and compact solution and can be integrated both with the multi-axis machining centers of the Performance Line series in the C400 and C650 models and with the C32 and C42 machining centers of the High Performance Line series.

Load capacity up to 1200 kg

The system is made of composite granite and the shape guarantees the operator easy and ergonomic use. The doors are designed with wing opening with the double safety function that block the access to the operator during the pallet change phase and allow the access to the working area during the workpiece machining.

The structure allows the handling of weights up to 1200 Kg including the weight of the pallet. When parts are loaded into the working area by crane, the permissible weight may even be higher. The maximum dimensions of the workpieces are 800 x 630 x 700 with the impossibility of loading larger workpieces already in the set-up zone in order to avoid possible operator errors.

The pallet changer system

A separate paragraph deserves the technical solutions adopted for the development of the pallet changer modules. In the basic standard version supplied by the company, only one module is installed but it is possible to add a second module offered as an optional when ordering. The modules have been studied and designed with a shelf design that guarantees the maximum degree of customization in the arrangement of pallets or pieces. Each module can be configured with a maximum of three racks and on each rack can be positioned up to 3 pallets. In total each module has 9 positions available with a maximum of 18 positions in double module configurations. The pallet changer can be configured quickly and intuitively thanks to the management software developed by Hermle itself.