Today we are talking about one of the timeless machines in the world of mechanics, a machine that boasts many purchase requests on our online catalog of used machine tools. Let’s talk about the grinding machine.

Functioning of the grinding machine

The grinding machine is a machine tool used to carry out finishing operations, often the grinding machine is characterized by a great structural rigidity.

As the name suggests, the grinding machine is used to perform grinding operations using tools called grinding wheels characterized by a fine and extremely hard grain.

The grinding operation carried out with the grinding machine is necessary in order to be able to bring any component into its optimal shape or surface condition as requested by the project.

This operation usually follows the roughing operations.

The previous roughing operation removes the “bulk” of the residues present on the piece, the subsequent grinding operation makes sure that all the excess residuals are eliminated by returning a surface finished with a high degree of finishing.

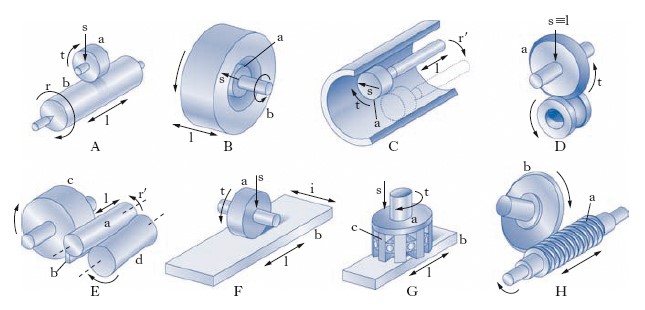

Depending on the type of processing and the surfaces to be treated we find a precise classification of the grinding machines, all widely available on the used market:

– grinding machines for flat surfaces (see our used surface grinding machines)

– grinding machines for cylindrical and conical surfaces (internal and external, see our used cylindrical grinding machines)

– centerless grinders (see our used centerless grinding machines)

– special grinding machines for screws and toothed wheels

Structurally, the grinding machine is composed of a bench or pallet that supports the work table and the vertical column. On the bench are also present all the mechanisms for controlling the longitudinal and transversal translation of the table and all the commands for controlling the motion of the wheel spindle.

The longitudinal translation movement of the work table is generated and controlled by an oleo-dynamic circuit which guarantees a smooth and constant motion despite the motion is generated by a gear transmission.

The motion of the wheel is constituted by a rotation which occurs both around a horizontal axis and around a vertical axis.

When the spindle axis is vertical, cup grinding wheels will be used in the grinding operations of flat surfaces and the grinding operation will be very quick and effective; the drawback will be represented by the traces of the grinding wheel passing on the surface itself.

On the other hand, when the spindle axis is horizontal, disk wheels with peripheral action will be used, allowing longitudinal grooves and grooved shafts to be machined.

In both cases concerning the machining of flat surfaces, the pieces will be fixed to the pallet of the piece-holder table by means of electromagnets or mechanically fixed with brackets and bolts.

As regards the grinding of cylindrical and conical surfaces, both external and internal, it is used the so-called universal grinding machine. It is so named because it is sufficient to make a small change to the tooling of the tailstock spindle so that these surfaces can be grinded.

If you want to grind external surfaces, the piece will be positioned between the main spindle and the tailstock, while for internal adjustments the piece will be positioned in the self-centering chuck and the grinding wheel will instead be positioned on the tailstock.

Instead, centerless grinders are used for grinding very long pieces. The piece is hold by a dedicated support, while it will be subject to the simultaneous work of two wheels positioned on oblique axes to each other. Thanks to the different positioning of the two axes, the progress of the bar will be generated during processing.

For the special operations of grinding screws and gears, will be used grinding wheels with suitably shaped wheels that will allow to work with the utmost precision.

If you are interested in buying used grinding machines, feel free to consult our online catalog of used machines where you will find a wide selection of grinding machines available on the market and many other used machine tools.