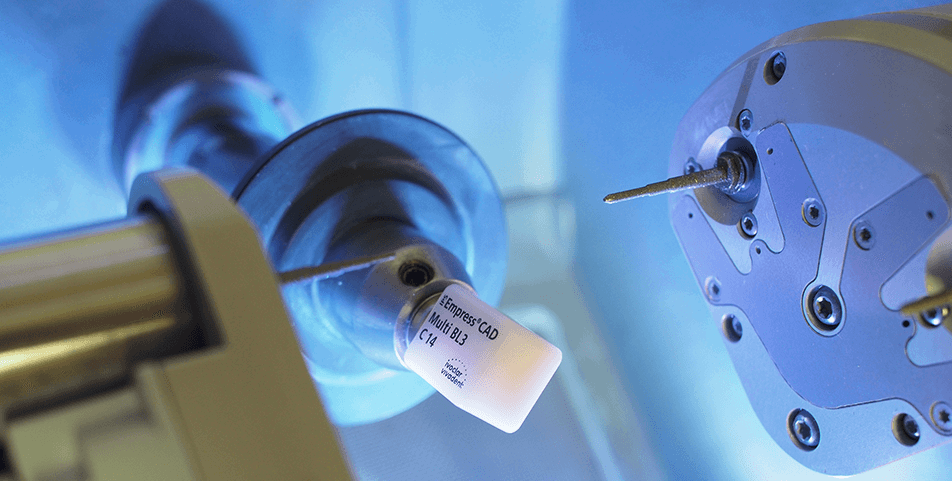

The hyperMILL® software is a very flexible solution in a single interface that allows you to program 2.5D, 3D and 5-axis milling and turning operations with extreme precision.

There is a wide range of machining operations that can be performed with machine tools, including High-Performance-Cutting (HSC and HPC) and High-Speed-Cutting. There are also special products from hyperMILL® for blisk, milling of turbine blades, pipes and tyre moulds.

Its advantages are manifold, such as:

Advantages

- Wide range of machining operations

- Integration into the main CAD systems

- Extensive automation

- Process safety through detailed simulation and collision control

- Continuous and efficient processes with significantly reduced times.

What’s new in hyperMILL® software version 2021.1?

The new version 2021.1 of the hyperMILL® CAD/CAM features a host of innovative functions for optimised surfaces in tool and mould design.

Simultaneous turning-milling

In turning-milling, Open Mind combines simultaneous turning with HPC machining. But that’s not all. There is also a new function in hyperCAD-S to easily align model and blank data.

This can be a major plus, especially when it comes to additive machining.

New integrated CAD

The CAD model adapts perfectly to the mesh model of the blank, because the algorithm offers the best calculation and alignment.

The user can enter various parameters to visualise the alignment. For example, he can lock the translation or rotation axes, or define a weighting between pairs of points.

In cases where a cast component or a part created with an additive process is awaiting rework, the “Best fit alignment” function can be used to adapt the CAD model of the part to the mesh model.

The user can use different parameters and display the alignment in the way he prefers. In addition, the user can lock the rotation or translation axes or define a weighting between the individual point pairs.

Optimised surfaces thanks to hyperMILL®

In order to allow a constant increase, the 3D profiling finishing has been integrated with the 90° Optimisation option.

In addition, the smooth overlap also contributes to the new 90° Optimisation function in Profiling Finishing. For example, if an area with an X orientation cannot be machined smoothly along a steep wall, it is automatically shifted to a Y orientation for a constant increment. However, the changes in the machining direction are not visible on the workpiece. With hyperMILL® 2021.1 it is also possible to modify tool travels retrospectively.

A new radial projection procedure

The new radial projection procedure allows rapid calculation of tool travels. In interactive mode, existing tooltravels can be selected and removed with maximum flexibility.

The know-how typical of milling allows the efficiency of turning machining. To combine all the advantages of HPC turning and simultaneous turning, the High Performance Mode has been made an integral part of the 3-axis Simultaneous Roughing.

At the touch of a button, it is done in a short time, but also safely.