Today we are glad to talk about the machining center, one of the queens of machine tools and modern mechanics. This is also one of the most requested used machines on Makinate, the company dedicated to selling and buying used industrial machines and equipment.

But let’s see together what is a machining center and how it works. We will provide you with a brief but exhaustive explanation.

If you are interested in this typology of machines, we invite you to have a look at our catalogue, you will find vertical machining centers, 5 axis machining centers, horizontal machining centers, and many other types of machining centers.

The machining center

Machining centers are multi-functional machines that allows with great flexibility to carry out an elevated number of mechanical operations, such as milling, boring, threading, drilling, etc., thanks to the ability to have a large number tools in the changer.

Machining centers can be various, according to the function, number of axes, the dimension of the working area, spindle position and the options available.

Typology of machining centers

However, the most important distinction is determined by the positioning of the spindle axis, hence the classification in two macro categories:

Vertical Machining Centers and Horizontal Machining Centers

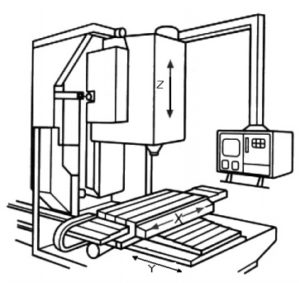

MAIN AXES OF MACHINING CENTER

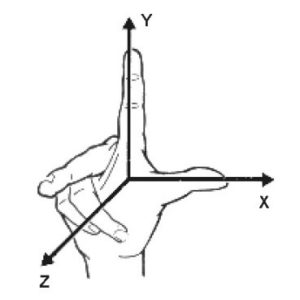

The arrangement of the axes in the machining center always follows the rule of the right hand

N.B. The Z axis is always matched to the spindle and its positive line is always in the direction of moving away from the workpiece

X Axis = Longitudinal

Y Axis = Vertical

Z Axis = Transverse

B Axis = Rotary Respect to the Y Axis

Technical specifications

Once determined the main classification of machining centers, now we are going to explain you how they are characterized them in the specific one.

First of all, it is important to define what is the working area or operating field.

The working area is defined by the size of the spindle operating area, depending on the x, y and z travel axes. Axis dimensions affect the maximum size of workpieces and the type of machining that can be done.

Once we have categorized the spindle position (horizontal or vertical) and axis dimension (x, y and z), we should also identify the following other important features:

- A number of controlled axes and fast-moving speed

- Number of tools

- Accuracy

- Spindle

- Power

- Speed rotation

- Taper toolholder

- Number of pallets

- Machine structure (cast iron that guarantees more stiffness and sturdiness or electro welded)

- Numerical control (CNC)

- With or without chip conveyor

Whenever you are ready to buy a used machining center you should consider all this information because of their importance. Depending on the type of production and necessary processes it will be necessary to address the search to

- An exact typology of machining center rather than another;

- A brand or model rather than another

The staff of Makinate is always available to help you from a technical point of view. We can find for you through the available machines on the market, the right machine for you and adapted to your production needs.

In one of the next articles, we will list all the features and characteristics that compose a machining center.

We are also going to describe in general, most of the numerical control machine tools.

Do not hesitate to contact us or to visit our catalogue of quality used machine tools available.