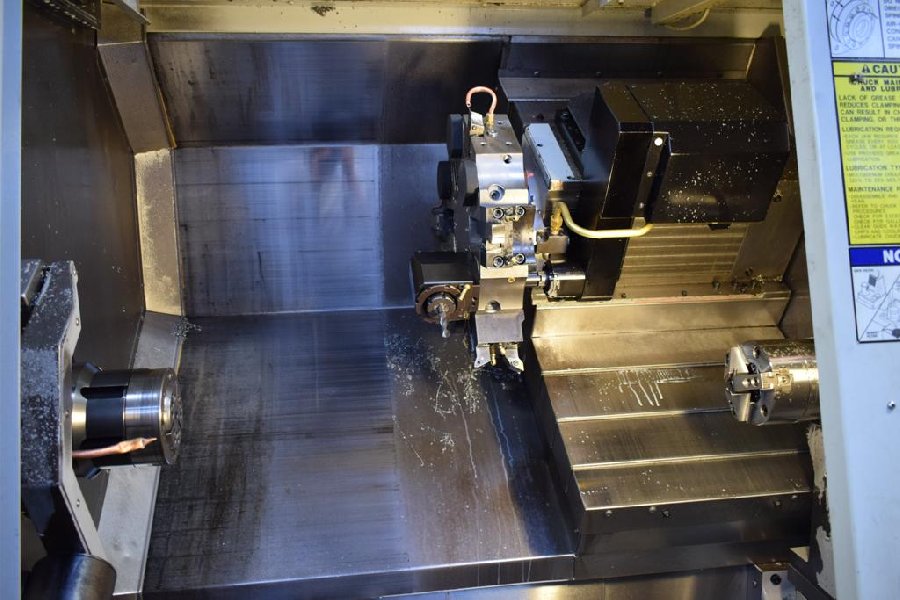

Good morning, after having described in a previous article the operating principles of the lathe, let’s take a further step in the deepening of this machine tool. Today, we will try to give you a brief but exhaustive explanation of the main classification that divides CNC lathes into two macro areas according to the type of machining they are intended for. We will talk about the macro distinction between cnc lathes for secondary turning and cnc lathe with barfeeder.

Cnc lathes

All CNC lathes can theoretically be used for secondary turning machining. By “secondary turning” we mean all those operations on mechanical parts that do not contribute to the mass production of a particular finished product. They can be all those turning processes that are combined with other processes carried out with other machines on the same piece and that together contribute to the production of the finished piece. Usually the pieces produced with secondary turning are unique pieces and therefore not mass-produced or they are produced in small numbers. Lathes intended for secondary machining can be either motorized lathes and therefore equipped with turrets housing live milling tools, or lathes with fixed tools. Depending on the complexity of the machining to be carried out, one or the other is chosen.

Cnc bar lathes

Cnc lathes equipped with barfeeders, as the name suggests, are lathes that work more automatically and contribute to the production of parts in series. Bar machining exploits the potential of the automation in order to produce large quantities of mass-produced parts. Cnc lathes for this kind of machining are equipped with so-called bar feeders that feed the bars fully automatically within the lathe’s working area as the planned machining requires. In production situations where we try to reach the highest levels of efficiency in terms of automation, in addition to the bar loaders or instead of them we could find automatic magazines with gantry structure and pick up device dedicated to the loading and unloading of the piece. These systems are called “gantry loaders”. Also cnc lathes with barfeeders can be equipped with live tooling turret or not, but normally the use of live tooling lathes is privileged in those who guarantee the realization of different machining operations in the same work cycle.

In both types of turning machining, sometimes the lathe is serviced by an anthropomorphic robot with the task of loading and unloading the workpiece, reducing to a minimum the intervention of the human operator. This particular technological situation is adopted especially in cases where the entire production process is to be automated, or when the physical characteristics of the part to be turned require it.